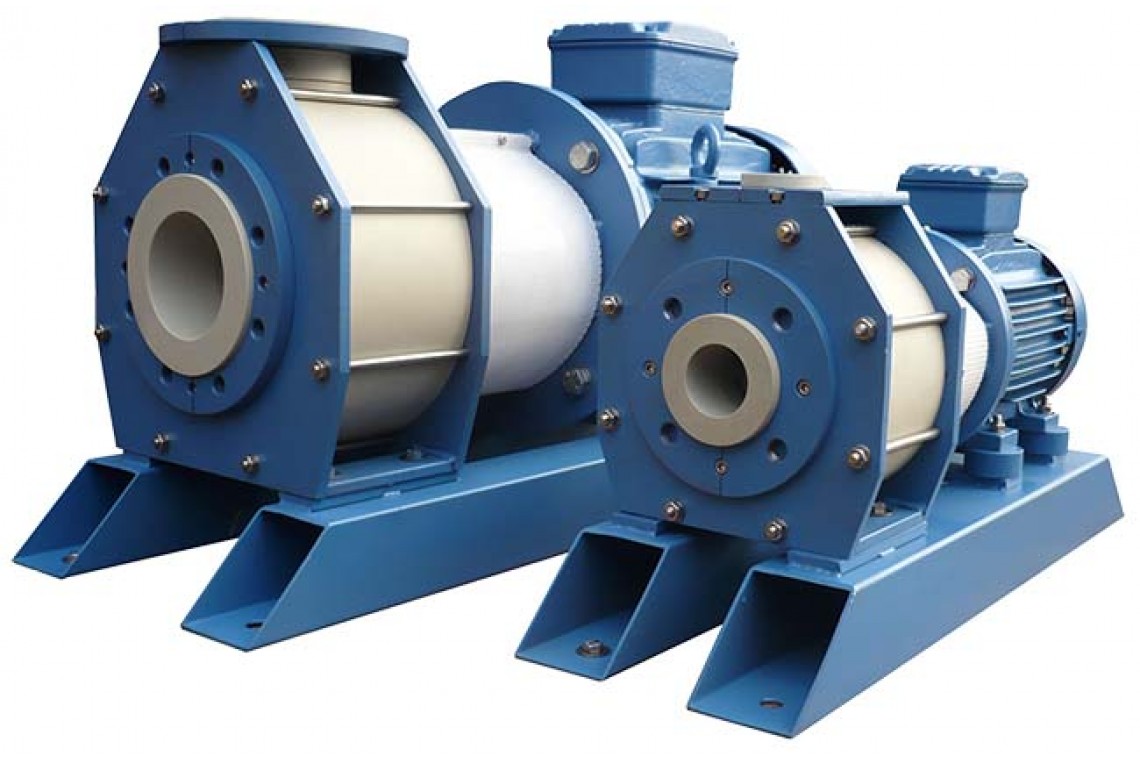

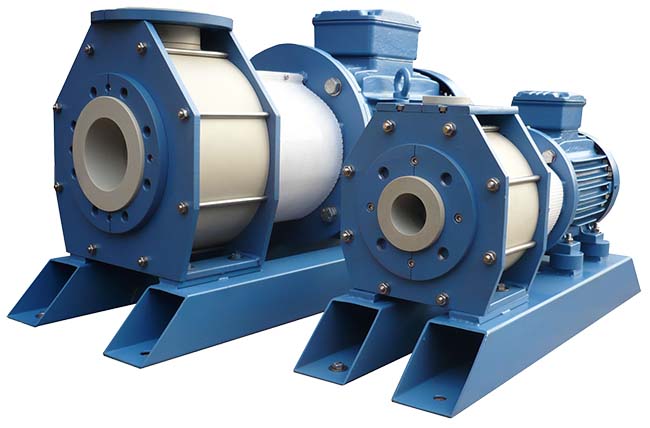

The PP range are designed to deal with some of the most corrosive applications in the industry and be fitted with a variety of mechanical seal options, making them suitable for a wide range of applications.

Priming chambers can be used with these pumps to allow suction lifts of up to 4.5m

- Capacity to 433 l/m (26m3/hr)

- Head to 22 meters

- Machined from Solid

- Handles Solids Efficiently

- Manufactured in the UK

- Corrosion Resistant

- ISO2858 specifications

- Choice of durable materials

- Flexible to design requirements

- ATEX Certification

parts are machined from solid blocks of plastic for the ultimate in robust construction. All pipeline forces are absorbed by a rugged steel shell.

parts are machined from solid blocks of plastic for the ultimate in robust construction. All pipeline forces are absorbed by a rugged steel shell.