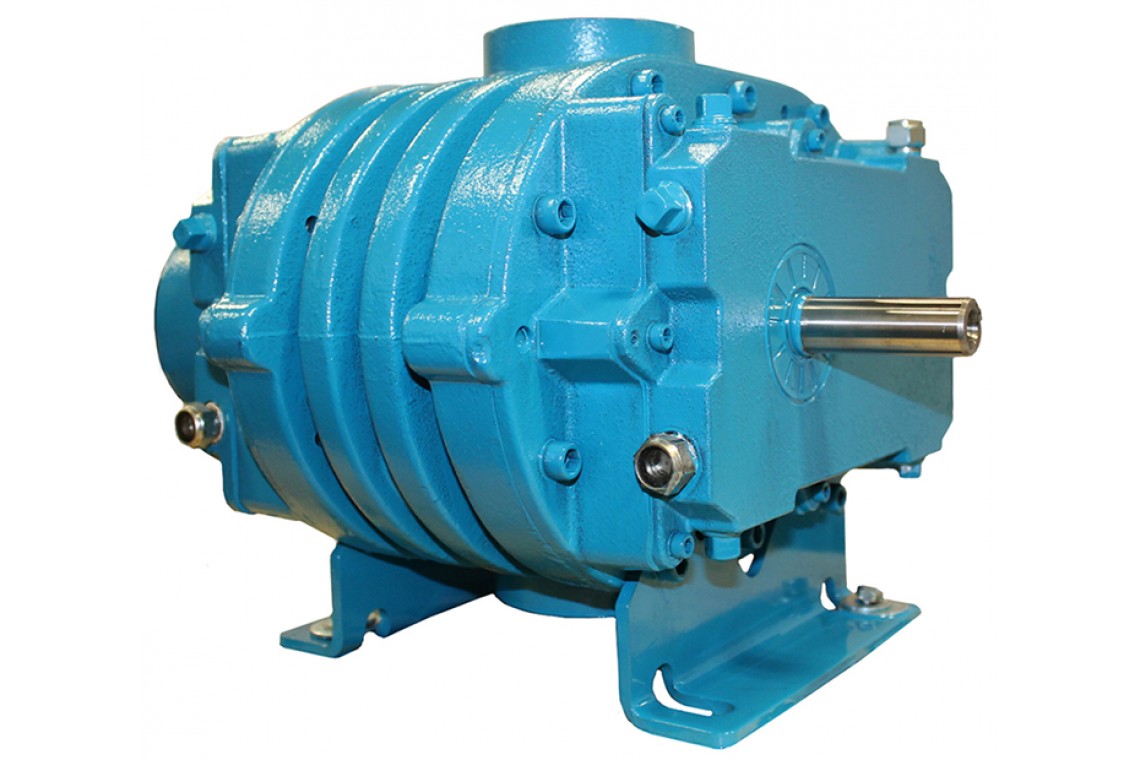

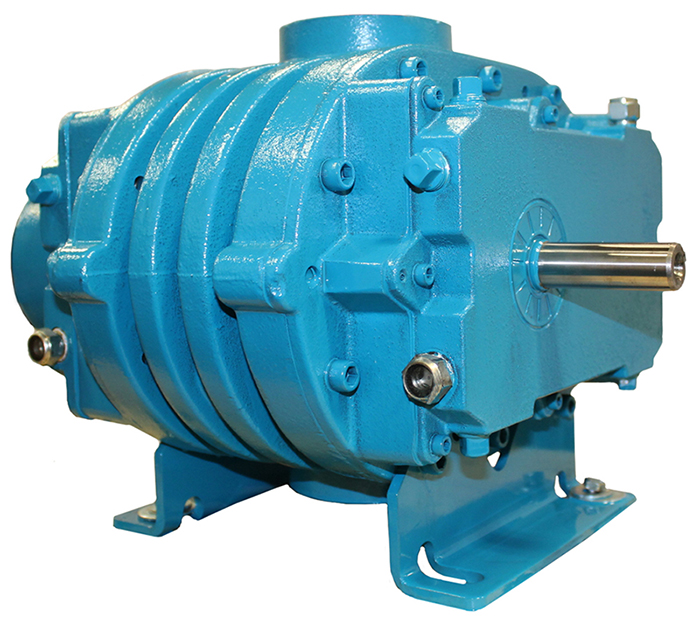

Our M-D Pneumatics™ rotary positive displacement blowers combine rugged  performance with flexibility as drop-in replacements to fit a variety of applications. CP Series blowers can be field converted from horizontal to vertical flow, or vice versa, without any special tools or additional components. CP Series rotary blowers are designed to be interchangeable with equivalent sizes of Roots Universal RAI® and many Sutorbilt® Legend® blowers.

performance with flexibility as drop-in replacements to fit a variety of applications. CP Series blowers can be field converted from horizontal to vertical flow, or vice versa, without any special tools or additional components. CP Series rotary blowers are designed to be interchangeable with equivalent sizes of Roots Universal RAI® and many Sutorbilt® Legend® blowers.

Continuous Power: Delivering up to 20% more power, CP Series offers models now rated up to 18 PSIG discharge pressure or 16” Hg dry vacuum.

Constant Protection: Standard on all models, triple lip seals extend the life of the seal and have been shown to provide longer bearing life. Magnetic drain plugs keep particles from moving through bearings and seals.

Stronger Bearings: All CP Series blowers include double-row ball bearings at the gear end, stronger than single-row ball bearings offered by other manufacturers. Drive shaft bearing is cylindrical roller type for additional strength against side loading from V-belt drives. CP Series bearing life is as much as 50% greater than models offered by other manufacturers.

Helical Gearing: CP Series blowers are timed with precision helical gears keyed to the rotor shafts, not taper-fit spur gears as offered by other manufacturers which have greater backlash, can slip and lose timing. Helical gears are also quieter, reducing mechanical noise.

Metric Availability: CP Series blowers are available with metric drive shaft and process connections.

Lubrication: Many CP Series models include dual oil splash lubrication at both the gear end and drive end of the blower. Splash lubrication provides for longer bearing and seal life through improved heat dissipation versus grease lubrication.

Reduced Noise Versions Available: CP Series standard models feature a bi-lobe design with integral shafts. Many models are available with tri-lobe rotors and a specially tuned housing to reduce blower noise.

*Models also available with splash lubrication