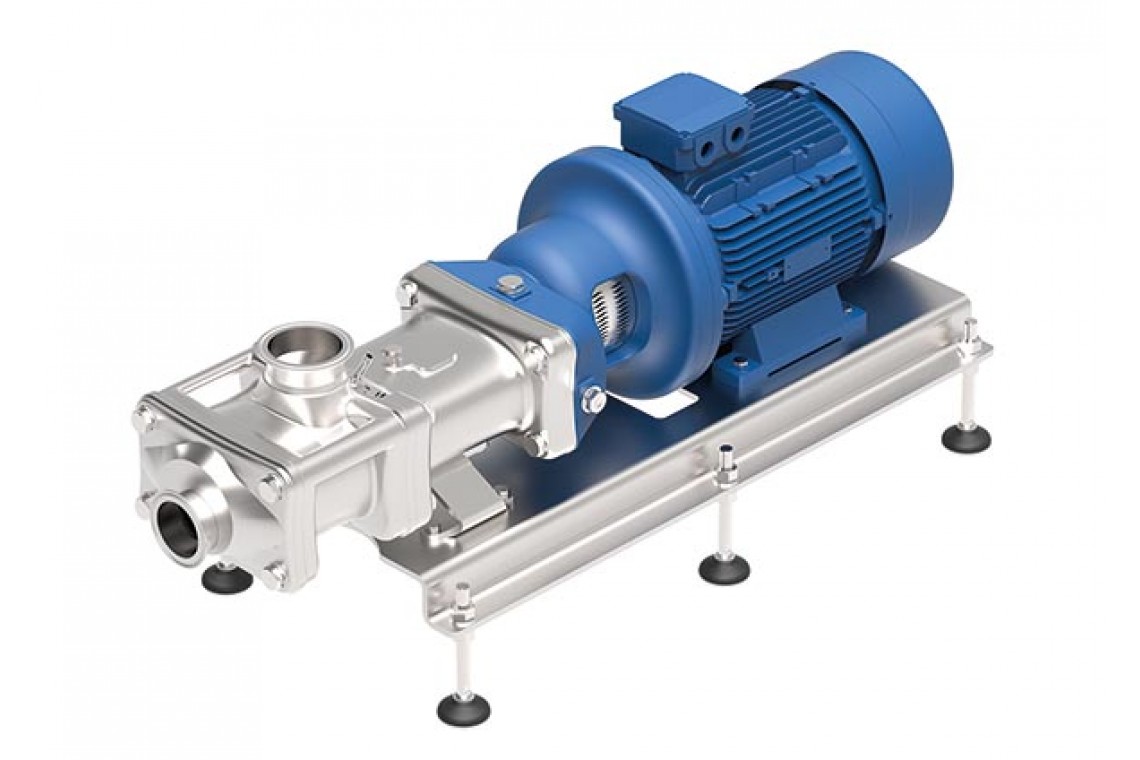

High suction performance The axial conveyance and the low acceleration of the product in the pump enables excellent NPSHR values < 2 m to be achieved.

| Low pulsation The axial pumping and low acceleration of product

|

Reversible conveying direction Pumping in both directions is possible by reversing

| |

Wide viscosity range Viscosities up to 1,000,000 mPa.s possible by axial

| Can run dry The contact-free operation of the feed screws and |

60% gaseous share possible The high speeds allow compressible products to be |