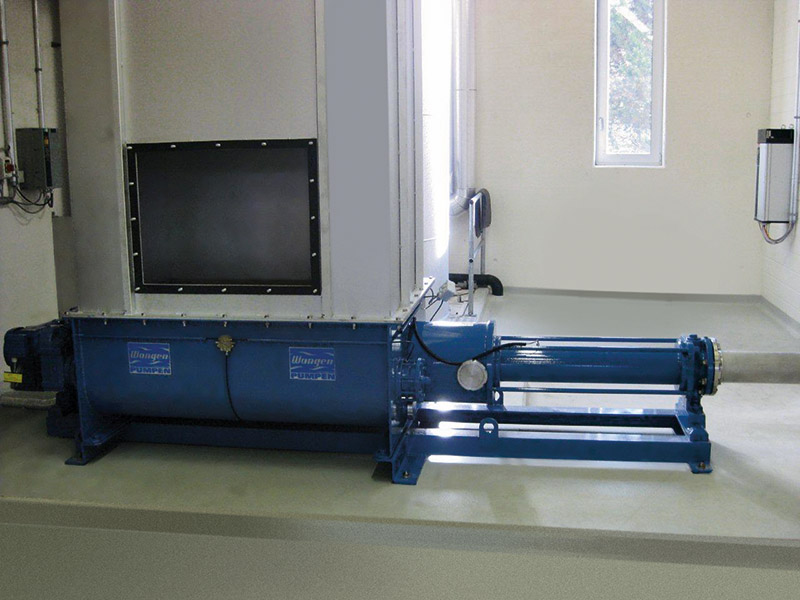

Pumps of the KL-RÜ series are built according to our proven modular principle. This allows high flexibility, low spare parts inventory, and minimum downtimes for repairs. Other features include: sophisticated and robust cardan joints with screw conveyors, fibers do not get wrapped around the joint and the joint connectors thanks to the effective protection device. Using an attachment hopper as an extension is possible. The KL-RÜ is available in various shapes, pump set sizes and rotor / stator geometries (S, L, and H shapes), so that the flexible choice of drive is the only logical consequence.